What is steel frame building?

A building consists of a supporting structure that keeps the building standing. Traditionally, many buildings in the Netherlands are built with solid materials. For years, there has been a trend towards more sustainable construction and lighter construction. Solid construction with concrete and stony materials is therefore on its way out. In addition, there is a desire to build faster in order to reduce building time and costs. The search for faster building methods has led to a greater degree of standardisation and prefabrication.

The steel frame construction method ideally meets these contemporary requirements and is therefore the construction method of choice.

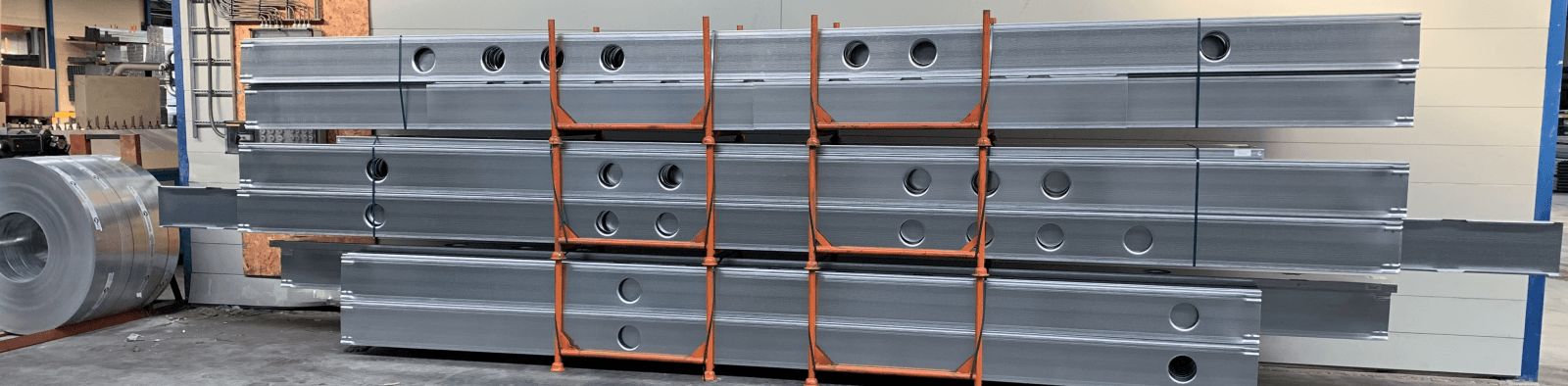

Steel frame construction is a skeleton construction method. The building is divided up into surfaces/elements. These elements are made of a skeleton with cladding on both sides. With the steel frame method, the frame is made from steel profiles. The steel frame profiles are made from thin sheet metal by roll forming machines. The required length, holes, chamfers and connections are made by computer.

Next, a contractor or subcontractor/framing company assembles these profiles into a frame. The wall frame can be fitted with insulation material and plasterboard on the visible side. In the case of façade elements, you will see that a different panel material is mounted on the outside, because extra thermal insulation and/or a façade panel material has to be attached here.

A vapour barrier is usually required on the inside to limit internal condensation. In the case of floor frames, a load-bearing board is fitted on top, such as 22 mm underlayment. On the underside of these frames, a plasterboard ceiling is attached at the building site.

These frames are assembled on the building site to form a building. Of course, you can also choose to assemble the frames at the building site and install the insulation, cladding and foil on site.

Weight

- Lighter construction allows for lighter foundations and much less settling.

- Low weight of the profiles makes assembly possible without a crane.

- Health and safety friendly installation due to the low weight of the profiles.

- No special tools required.

- Easy installation of plumbing, heating, electrical and sanitary installations.

- Dust-free and low-noise installation.

- No time-consuming drying times in the construction phase.

Strength:

- Extremely high strength of steel.

- More usable space thanks to slimmer structures.

Stability and earthquake resistance:

In the event of earthquakes and heavy winds, large horizontal loads will arise in the structure. Due to the extremely high strength of steel, these can be absorbed and passed on. The light weight of the entire skeleton will reduce the forces. A high earthquake resistance will therefore be more easily achieved in combination with a solid foundation. Steel frame provides increased safety for the residents.

Fireproof:

- Steel is non-combustible and will not contribute to a fire.

- Short circuiting of electrical installations in walls and floors will not be able to cause a fire.

Ecological:

- Steel is 100% recyclable.

- No waste due to custom production of all components, therefore less material and no waste costs.

- Longer life span.

- Don’t forget the ecological aspect of steel framing: “Forests are preserved when buildings are made!“.

Advantages of steel frame construction?

Steel frame construction is the building system of the present and of the future and this is actually very logical: steel frame is ideally suited to today’s higher demands on buildings: sustainable, ecological, low-energy, impermeable, earthquake-proof, industrial, fast, flexible, adaptable and with a short construction period. The total building concept for now and the future.

Freedom of creativity and design:

- The high strength of steel and flexibility of the profiles allows for almost any design, even with larger floor spans. The building is designed entirely on the drawing board and the profiles are produced from this drawing directly in our factory, eliminating the risk of errors and subsequent necessary modifications.

Accuracy:

- The flatness, dimensional stability and tightness of the profiles ensure high-quality finishes and better crack and air sealing.

- Precise construction due to industrial manufacture of the profiles.

- Tightness. No expansion or contraction due to moisture.

- The modularity of the profiles provides a perfect connection to connecting materials.

Mounting:

- Easy to assemble, no specialist required.

- Installation possible without heavy tools and taps.

- Dust-free assembly.

- Installation possible under all possible site conditions (rain, snow, sun, spring, summer, autumn and winter).

- Low risk of disturbances on the building site.

- Short construction time.

- Dry construction method; no negative moisture impact on building materials used. No long drying times and no shrinkage cracks.

- Leent zich uitermate goed voor prefabricage.

- Health and safety friendly installation due to the low weight of the profiles.

Durability:

- Steel profiles do not rot, do not split, do not warp or split, and do not suffer from time-dependent creep.

- No infestation by vermin (insects, worms or rodents).

- High corrosion resistance due to zinc coating.

- Leaks do not lead to the replacement of beams or posts.

Economical:

The final price of the building is substantially lower than that of conventional constructions. (Good price/quality ratio)

From plan to execution

Steel frame construction is not yet a standard construction method. The traditional building process does not apply to steel frame construction. In the meantime, however, there is more than 25 years of experience with this construction method and there is therefore sufficient certainty that this construction method is satisfactory in practice.

The realisation of a steel frame building is somewhat different from the traditional method. In the preliminary stage, a designer/architect will make a design as usual, after which the structural engineer and/or structural engineer will elaborate this design in a digital working environment (CAD, REVIT, etc.); or Easy Housing in Tekla.

With this digital drawing and the constructor’s necessary dimensions, the designer can draw the required steel frame profiles exactly. We deliver our product-library/family digitally. Using applications in the drawing software (like Tekla) the steel frame parts can be exactly determined and drawn. Coiling, slitting, stretching, punching, cutting, bending, punching-nibbling, roll forming, profiling, setting, edging, water cutting, sparking, turning or milling? You can leave it to us.

With the digital printout of these profiles, the machines in our factory can be controlled directly. We label all profiles according to the specification from the drawing. This minimises the risk of errors on the building site and allows us to work with smaller construction tolerances. In the end, everything will arrive at the building site exactly to size. The contractor can choose to have the frame prefabricated by a subcontractor or he can screw it together himself on the building site according to the digital drawing.

Below is the schedule of the work

| Architect | Structural engineer | Easy Housing | Subcontractor

framing |

Main contractor | |

| Design | x | x | |||

| Engineer | x | x | |||

| Production | x | ||||

| Framing | x | x | |||

| Assembly | x | x | |||

| Finishing | x |

There is also an intermediate form. The subcontractor uses the contractor’s drawings only as a basis. He then only draws the necessary contours of the building. The subcontractor then works out the necessary drawings of the steel frame construction into a production drawing in his own drawings. The advantage that the actual steel frame construction is in the original building drawings (BIM model) and therefore in case of changes, the consequences are immediately visible, does not occur then. The installer, finisher, etc. also cannot see exactly where the steel frame construction parts are located. They will then not be able to fine-tune their work and avoid extra work and errors in the realisation